Detroit’s Auto Layoffs: A Tale of Transformation, Not Tech’s Excess

Over the past several months, the technological sector has been affected by wave after wave of layoffs among such giants as Google, Meta, and Amazon. The reasons have gotten used: the pandemic boom of over-hiring, too much mimicked work, and the much-needed corrective after years of irresponsible expansion. However, as Silicon Valley took most of the headlines, a much less wave of job losses had been taking place deeper into the industrial heart of America in Detroit. On the outset, General Motors, Ford, and Stellantis announcement appear to be a continuation of the same economic slowdown. They aren’t. The situation in the auto industry is more than a mere correction step; it is a painful, once-in-a-generation reinvention that is taking place due to the switch to electric vehicles.

These layoffs are not merely about cutting fat it is a fundamental rewiring of an entire industry which has set the tone of American manufacturing in a hundred years. The internal combustion engine is gradually dying out and the expertise, factories and supply chains that surround it are being phased out. Simultaneously, there is a desperate need of new knowledge in the fields of software, batteries, and electric drive trains. This is an expensive, unpredictable, long process and the human price is being paid in thousands of lost employment not only in Michigan but in other states as well. The case of Detroit is an example of reconstruction, not reduction and it is worth a closer examination.

1. The Big Three of Detroit Suffers the Wave of Layoffs

The figures that Detroit has produced over the last few months have been grim. General Motors, Ford, and Stellantis have set forth large scale layoffs of workers, most of them based in Michigan. These are not minor changes; thousands of wage earners, tech centers and assembly lines, are impacted. The peculiarity of the situation is that these announcements follow in waves, and a large number of employees have devoted decades of their lives to the industry and have no idea when the situation will end.

The cuts are not in panic, they are strategic as seen behind the headlines. The automakers are preparing to endure a long period of sluggish demand, increased cost, and the astronomical capital needs of the electric-vehicle transition. In contrast to the widespread layoffs in the tech sector, Detroit layoffs have to do with literalities of overhauling an industry and still attempting to make a profit on new models. The hurt is there, but it is in a bigger, inevitable change.

2. Not a Panic Strategic Cost Management to Tough Times Ahead

The analysts in the industry believe that these actions are calculated and progressive. Patrick Anderson of Anderson Economic Group has termed the auto industry as quite obviously slowing down with firms actively reducing expenditures in the expectation of a weak demand or even a recession. Instead of responding to an acute crisis, the leaders of Detroit are attempting to save cash and agility to make the long-term journey.

This is unlike some of the less gradual layoffs of tech which sometimes seemed to be a sudden turnaround after years of intense growth. Car makers have survived through several economic cycles and are aware that a fortunes can turn around so fast. Their desire to cut now is to prevent further cuts in the future should consumer spending become further restrained and/or the EV market underperform even more than it has been doing.

Reasons Experts give why Proactive Cuts are necessary:

- Getting ready in case of an even greater economic downturn.

- Controlling the expenses associated with ballooning of EV production and development.

- Holding cash as a reserve investment in electrification.

- Reacting to declining aggregate car sales in the U.S. market.

- Remaining competitive with the low-cost international competitors.

3. The Electric Elephant in the Room: Huge EV Investment Losses.

The most shocking part of the situation in Detroit is the high price of electric conversion. New platforms and battery plants and software development are being invested in to the tune of billions of dollars, not to mention that most electric models continue to lose money with every unit sold. This has been made openly clear in the statements of General Motors since though its EVs are nearly making a profit, the company still is bleeding red ink on electrified vehicles.

This economic pressure compels hard decisions: the postponement of the release of new models, laying down the factories, reducing the pace of the production line. There are plants such as GM, Orion Assembly that are on standby when the company is waiting until demand can match ambition. It is an age old gamble on the future that is spending heavily today to take over tomorrow but it is the present losses that cannot be ignored and are actually leading to the necessity of workforce cutdowns.

Financial Push of the EV:

- Hundreds of billions into battery plants and new EV platforms.

- Various vehicle releases deferreed to save on capital.

- Factories were idle awaiting the recovery of consumer demand.

- Huge dependence on government subsidies to bridge the price difference.

4. EV Revolution Slows with Consumer Disdain

Even despite the years of marketing and policy promotion, electric cars have not been adopted among American shoppers as automakers expected. The EV market share remained around 7 percent most of 2024 and it was only recently that it reached 9 percent, a far cry bigger than the aggressive targets set only a couple of years earlier. Such industry observers as Patrick Anderson observe that this consumer reluctance can no longer be overlooked.

The largest obstacle is still high prices, as the average EV is priced at about 8,000 higher than a similar gas-powered one. Confusion regarding charging system, range and resale value are also keeping most shoppers at the periphery. This is forcing car dealers to turn to cutthroat leasing offers and discounts to clear stock which is already already narrow.

Factors Driving Consumer Hesitation:

- Average EV price around $56,000 versus $48,000 for gas vehicles.

- Limited public charging infrastructure outside urban areas.

- Concerns over battery life and long-term resale value.

- Preference for familiar gas-powered trucks and SUVs.

- Roughly 80% of EV buyers now choosing leases over purchases.

5. A Generational Layoff: Obsolete Skills Meet Emerging Needs

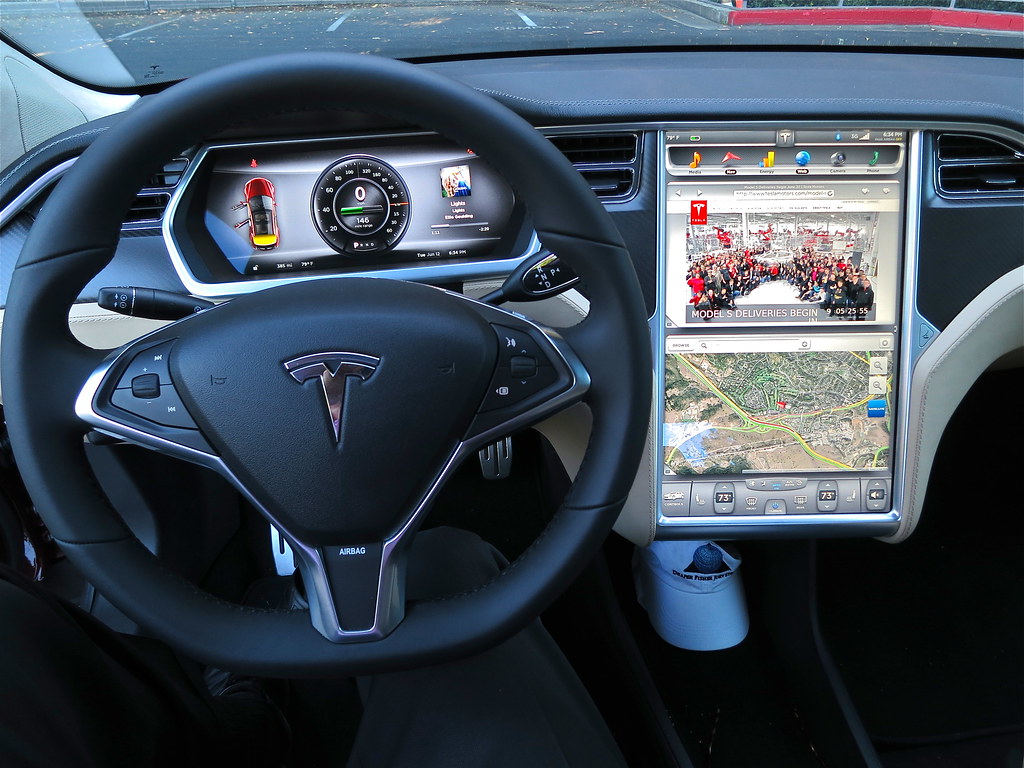

What sets Detroit’s layoffs apart most clearly from Silicon Valley’s is their nature. Chris McCarthy of North Highland calls them a “generational layoff” jobs tied to internal combustion engine technology are disappearing, while demand surges for entirely new skill sets. This isn’t broad efficiency trimming; it’s a targeted metamorphosis.

The industry isn’t shrinking overall it’s changing shape. Roles in traditional powertrain engineering and mechanical assembly are declining, while software development, battery systems, and autonomous-driving tech are growing fast. Workers with decades of experience in one domain suddenly find their expertise less relevant, creating a painful but necessary transition period.

Shifting Skill Demands in Modern Auto Manufacturing:

- Decline in traditional mechanical and powertrain engineering roles.

- Rapid growth in software programming and coding positions.

- Increased need for battery chemistry and electrical systems experts.

- Rising demand for data scientists and AI specialists.

- New focus on cybersecurity for connected vehicles.

6. Silicon Valley Takes Notes from Detroit’s Playbook

Interestingly, some analysts believe the tables have turned: tech companies may now be learning from Detroit’s decades of experience managing industrial cycles. Martin French of Berylls suggests that tech giants are deliberately slimming down in advance of a potential downturn, borrowing a page from how automakers have historically braced for recessions.

While Silicon Valley once seemed immune to traditional economic swings, the post-pandemic reality has shown otherwise. By cutting early and deeply, tech leaders hope to emerge stronger just as Detroit has done multiple times before. The student has become the teacher in navigating leaner times.

Ways Tech Is Mirroring Auto Industry Tactics:

- Proactive headcount reduction ahead of confirmed slowdown.

- Focus on core priorities and highest-margin products.

- Streamlining organizational structures for speed.

- Building larger cash reserves for future investments.

- Accepting short-term pain for long-term competitiveness.

7. Global Competition Intensifies, Especially from China

This burden on American manufacturers has been increasing in strength in recent years, as Chinese manufacturers become the key players on the EV market of the world. Other firms such as BYD have developed capacity of expansion and innovation at a pace that frequently surpasses that of the U.S. firms in the introduction of new models and lower costs. This has enabled Chinese brands to take a large market share across the globe where millions of vehicles have been exported and has competed with the traditional market giants in terms of cost and technology.

In the case of the Big Three GM, Ford, and Stellantis, the danger is evident since with no radical efficiency actions, they will lose ground not only overseas but also possibly domestically in the event of a trade obstacle change. The executives have also made arguments many times that it is necessary to simplify the operations and devote resources to keep up with the competition in this new environment where speed and size are biased towards foreign competitors.

Significant Competitive Menaces to the U.S. Automakers:

- Chinese companies such as BYD had surpassed Tesla as the largest EV seller in the world in 2025.

- High overcapacity production in China with the capacity to produce at a lower price and timely model changes.

- The fast Chinese globalization through brand expansion to Europe and other markets.

- High battery and materials supply chain and high technology EVs.

- Risk of more exports taking over U.S. market share in case of policy changes.

8. The presence of Political and Regulatory Uncertainty is a Pressure

The political climate has brought the EV transition even more volatility. The federal tax credit of $7,500 which was one of the major motivators of consumer adoption was discontinued after September 30, 2025, resulting in a sharp rise in purchases before that date with a sharp decline afterwards. These incentives had been the basis of automaker plans and their abrupt cancelation put demand estimates on their toes and made them change their plans at high speed.

Regulatory changes such as the possible alterations in emissions regulations and trade policies among others remain a source of uncertainty. Such leaders as Mary Barra of GM have emphasized the fact that varying rules may make it difficult to make billion-dollar investment decisions and in doing so complicate the ability to make long-term investments in EVs, and continue to make money on current models.

The most important Political Risks that may affect the EV Transition:

- Removal of federal tax credit of up to $7,500 on EVs after September 2025.

- The possible changes to the fuel-economy and emissions rules.

- Supply chain and import cost trade tariffs.

- Incentive programs on a state level that are susceptible to changes in the budget.

- There are continuous policy debates affecting consumer and corporate planning.

9. The Michigan Paradox: Large Subsidies, Small Number of New Jobs to Date

Michigan has had mixed success in its aggressive invitation of EV and battery production with more than 1 billion incentives. Although GM, Ford, and other projects guarantee thousands of jobs in the future, the development has been slower than expected, with a lot of premises postponed or reduced in size due to a declining interest in EVs. The investments have yet to yield any appreciable employment in the proportion of the predicted employment, and this shows the delay in subsidies versus actual economic influence.

The postponements do not stop the determination of state leaders and companies, which consider the current slowdown to be only temporary. The continued construction of the headquarters of GM in Detroit and the reassurances of Stellantis attest to a long-term commitment to Michigan as a center, despite the numbers of jobs being dismal in the short run.

Mixed Results of EV Incentives in Michigan:

- More than $1 billion of invested funds, yet projects were usually forced behind or cut.

- Sluggish creation of jobs so far, well short of the promises.

- Certain controversial plants that have either received local opposition or are under review of funding.

- The sustained corporate investments as an indication of the future possibility.

- The shift to retraining new EV related jobs.

10. Looking Ahead: Pain Today, Resilience Tomorrow

By the year 2026, the change in Detroit will still be a process in its early phase that will adjust itself to the new reality through continuous changes, financial write-downs, and the shift toward hybrids and pure EVs. The industry has proved to be resilient and the total U.S. vehicle sales have remained unchanged in 2025 irrespective of the challenges posed by EVs due to the high level of truck and SUV sales. However, the human and financial price of such a transition can be seen in the continuing layoffs and closing of plants.

Finally, it is a tale of adaptation but not a story of downfall. Rediscovering ways to approach the world with software integration, seeking efficiency, and planning to compete in a multi-powertrain future Detroit hopes to become a competitive place in the world that is becoming more electrified and globalized. The question remains, will this generational shift bring about a new surge of strength, or will the lost opportunities give other people time to shape the next generation of mobile?

Core Elements of Detroit’s Future Vision:

- Balanced approach incorporating EVs, hybrids, and efficient gas models.

- Heavy investment in software and autonomous technologies.

- Streamlined operations for agility against global competitors.

- Workforce retraining to bridge traditional and new-era skills.

- Long-term commitment to Michigan as a manufacturing cornerstone.